About this technical documentation

Introduction

This manual is a quick guide to the operation and maintenance of the Ultrasonic Gas Meter, models Ugr.

The manual contains important instructions to prevent accidents and serious damage before start-up, during operation, and to ensure trouble-free operation in the safest possible way. Before using the product, read this manual carefully, familiarize yourself with the operation of the product, and strictly follow the instructions.

This manual is based on the latest information. It is provided subject to alterations. We reserve the right to change the construction and/or configuration of our products at any time without obligation to update previously shipped equipment.

Ultrasonic Gas Meter

General

The Ultrasonic Gas Meter is a sophisticated, ultrasonic gas flow meter manufactured by Pioneer. It has been specifically designed for residential gas measuring applications that demand a high degree of accuracy and reliability.

Applicable standards

The Ultrasonic Gas Meter is manufactured to be in accordance with European Standard: EN14236-2007.

Calibration

When using the Ultrasonic Gas Meter, most countries demand (by law) a calibration from a certified calibration institute, supervised by an inspector of quality and measures.

Dashsheet

| Parameters | Unit | G1.6 | G2.5 | G4 |

| Nominal measured flow Qnom | m³/h | 1.6 | 2.5 | 1.6/2.5/4.0 |

| Maximum measured flow Qmax | m³/h | 2.5 | 4 | 6.0 |

| Minimum measured flow Qmin | m³/h | 0.016 | 0.025 | 0.040 |

| Lowest flow rate Qstart | m³/h | 0.004 | 0.004 | 0.004 |

| Error – Qmin ≤ Q < 0,1Qmax – 0,1Qmax ≤ Q ≤ Qmax |

% | ± 3.0 ± 1.5 |

± 3.0 ± 1.5 |

± 3.0 ± 1.5 |

| Transitional flow rate Qt | m³/h | 0.1Qmax | 0.1Qmax | 0.1Qmax |

| Maximum working pressure Pmax | kPa | 50 | 50 | 50 |

| Pressure Loss at Qmax | Pa | ≤200 | ≤200 | ≤200 |

| Counter capacity | m³ | 999999,999 | 999999,999 | 999999,999 |

| Minimum counting division | m³ | 1 | 1 | 1 |

| Ambient temperature tm | °С | -25 to +55 | -25 to +55 | -25 to +55 |

| Gas temperature range tg | °С | -25 to +55 | -25 to +55 | -25 to +55 |

| Base gas temperature tb | °С | 15 | 15 | 15 |

| Storage Temperature | °С | -30 to 70 | -30 to 70 | -30 to 70 |

| Humidity | % | ≤95 | ≤95 | ≤95 |

| Power supply | Li battery | Li battery | Li battery | |

| In- and outlet pipe screw | iNCH | G11/4 (ISO228) | G11/4 (ISO228) | G11/4 (ISO228) |

| Distance between inlet and outlet | mm | 110 | 110 | 110 |

| Protection Level | Class | IP66 | IP66 | IP66 |

| Mass, not more than | kg | 2.5 | 2.5 | 2.5 |

| Overall dimensions | mm | 228*104*152 | 228*104*152 | 228*104*152 |

| Medium | NG | NG | NG | |

| Design Lifetime | Year | 15 | 15 | 15 |

Roduct Description

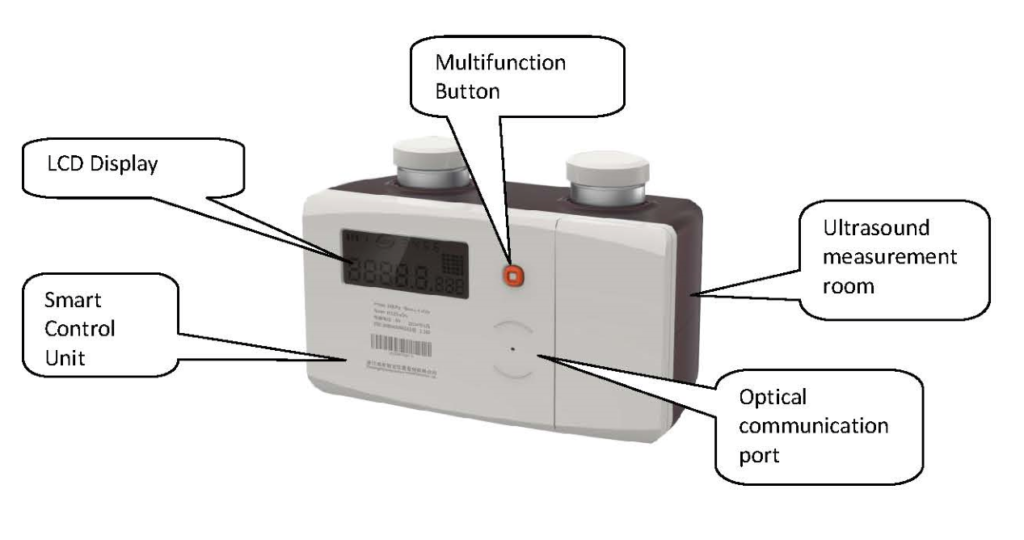

Ultrasound Measurement Room

The ultrasound measurement room is a complete sealed room where gas flow is measured. The gas flow channel, ultrasound sensors, signal process board, temperature sensor and shut off valve are built in this room.

Smart Control Unit

The smart control unit consist data calculation, storage, LCD display, valve control, local optical port communication, calibration, a D size Li battery and so on.

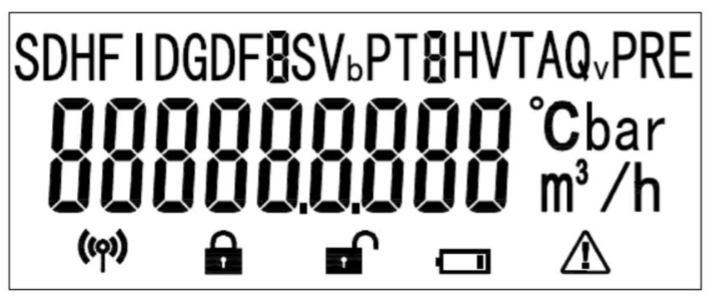

LCD

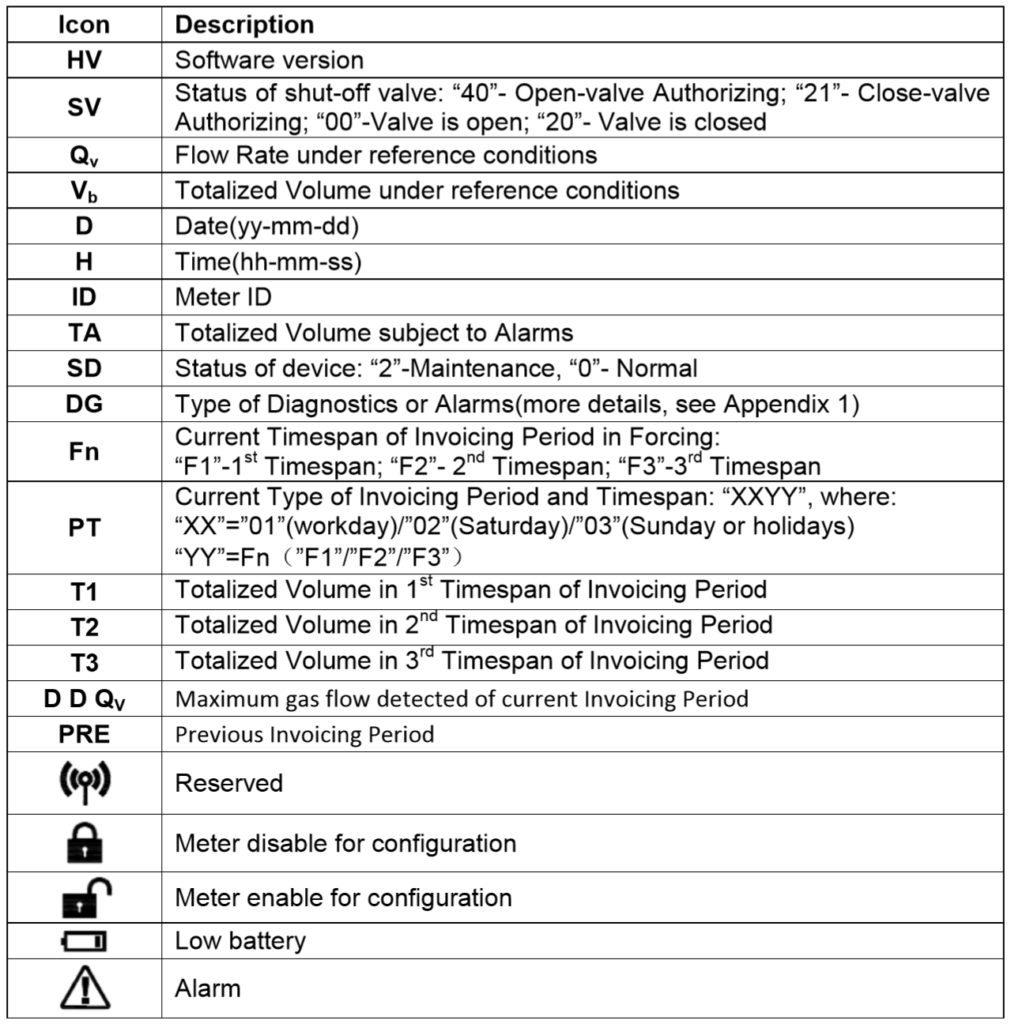

The LCD display all the information and parameters, such as gas consumption, working condition, temperature, Meter number, firmware version and so on.

Optical Communication Port

PC, Hand held unit or test bench can communicate with meter through optical port to do the calibration, configuration and so on.

Multi-function Button

This button is used for activate LCD display, optical port enable and activate the open of shut off valve with the authorization from system command.

Labels and nameplates

Nameplates and labels are used to identify the product and to provide details on the specific product. Together with the product manual it specifies how the product is certified and designed.

Installation

This Chapter describes the important notes for the installation of gas meter.

- Installation in the horizontal position.

- Note the direction of gas flow ( arrow )

- Ensure that there is sufficient installation and operation space.

- Ensure unobstructed view of LCD display and replace the battery.

- Connections: G11/4’’ ISO228 – The U-GR Ultrasonic meter is designed with High level protection, so it can be installed in the house and outside of house without additional box.

Operation

This chapter describes how the Ultrasonic gas meter can be operated through the LCD, button and optical communication port.

Meter reading

LCD provide an overall status indication of the meter.

Standard/Testing mode

When meter is installed in the field, it should be kept in the Standard mode. The testing mode is only for meter accuracy testing in the factory. When in the testing mode, there will be a digit increase quickly to indicate the test mode; the resolution of volume will be 4 digits. The temperature compensation will be closed. the RED LED will blink according to the gas flow rate which can be used to high efficiency accuracy calibration with Pioneer’s own designed test bench. The change between Standard/Testing modes only can be executed by the professionals from Gas Utility.

Valve operation

The inside valve is the key part of this smart ultrasonic gas meter. The valve can be configured to automatic close once the below events occur:

- Detect the abnormal gas flow(Leakage)

- Detect the reverse gas flow;

Real time clock

The meter has an internal real time clock which supports the Tariff, billing functions.

Billing

This meter records the previous invoicing period billing data which can offer the gas company a precise and efficiency billing solution.