NB IoT Manhole Water Level and Flow Monitoring Solution

In order to monitor the discharge and capacity of the urban pipe network and the actual discharge of industrial, domestic sewage and rainwater, the liquid level in the downstream pipe monitoring wells should be acquired in real time to provide data support for the upstream discharge control and treatment.

In particular, when the actual discharge exceeds the capacity of the pipeline, the downstream pipeline will be flooded, that is, when the height of the liquid level in the monitoring well exceeds the set threshold, timely mitigation and dredging measures should be taken to avoid secondary disasters.

This intelligent monitoring product can measure the liquid velocity in the pipeline and the liquid level height in the monitoring well in real time, process the data by algorithm and perform compensation calibration, and convert the data into flow data.

Secondary development can be carried out to present the measurement results through the browser or the mobile phone client. If there is abnormal flow or monitoring well level height beyond the threshold, the system will issue an early warning and alert and push it to the mobile phone client. Can also actively view real-time monitoring results and achieve query statistics.

Working Principle

Flow calculation method:

The two related quantities of indirect measurement of flow rate, namely liquid velocity in the pipeline and liquid level height in the monitoring well, were used to calculate the flow rate in the pipeline, namely Q=S*V, Q= pipe flow rate, S= section area, V= liquid velocity

• Algorithm 1.

Measure the liquid velocity and liquid level height in the pipeline, obtain relevant parameters by consulting the table according to the fluid characteristics of the pipeline, and modify the velocity at different liquid levels;The constant flow area of the pipeline was calculated by the liquid level height, and the liquid flow rate Q1 in the pipeline was obtained.

• Algorithm 2.

Measure the liquid velocity and liquid level height in the pipeline, calculate the constant flow area of the pipeline, and obtain the liquid flow rate Q2 in the pipeline.

Flow Q1 and flow Q2 are mutually compensated to obtain liquid flow Q in the pipeline.

Description

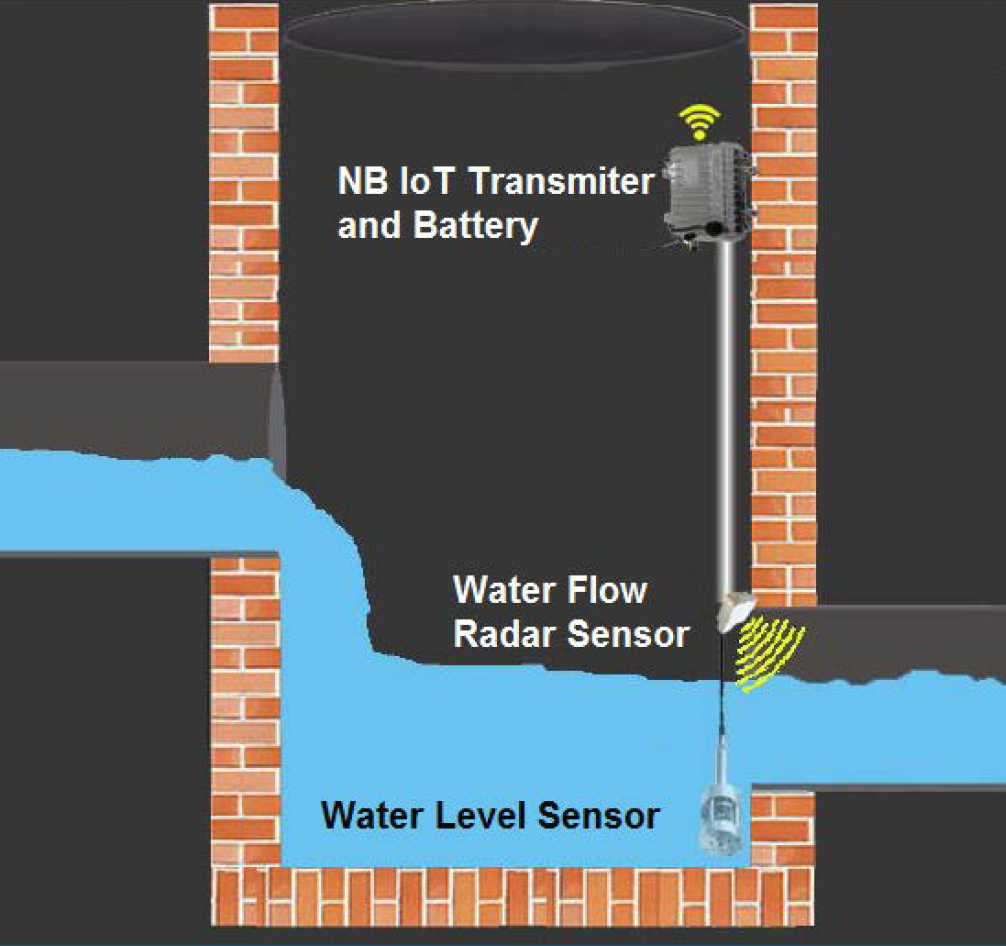

• The monitoring device is installed at the downstream pipe entrance of the monitoring well, as shown below.

• The level sensor is put into the bottom hole liquid, and the current meter is installed as shown in the figure.

• The waterproof tube is fixed on the wall of the well, and the liquid level sensor and the velocity meter are connected to the NB IoT transmiter through the waterproof tube.

• Solar and battery power are used, and solar panels (optional) are introduced into the monitoring well through cables to provide long-term power to the equipment.

• Data is transferred to the cloud platform server in NB IoT mode.

Main Features

Sensors:

• Liquid level sensor: input type (static pressure) + counterweight plate

• Current meter: non-ontact radar measuring current sensor

Transmission mode:

• NB IoT long-distance transmission, easy to expand

Main features:

• Low cost, easy to install and maintain

• Real-time remote monitoring

• High accuracy, precision optional

• Applicable to all kinds of pipelines, open, full or half pipe flow monitoring;

• Applicable to sewage, rainwater, industrial wastewater discharge monitoring;

• Can be used in wet and corrosive environment;